We’re here to solve your design problems and help with a successful installation.

All our products are created with your customers in mind. We can create 1 offs as well as a large production of many units and also provide the possibility to change a lot of options to fit your needs.

Why choose plastic works systems?

Our Capacity on deliverables provided we have the plans, and designs completed we make it a point to reach the desired completion time agreed upon by both parties.

01

Technical

(Material Property Sheets) Physical and mechanical properties including; density, electrical conductivity, coefficient of thermal expansion, tensile strength, yield strength, elongation, reduction of area, hardness, impact strength, and bend ability.

Safety Data Sheets (SDS/MSDS) are the internationally standardized way to document the hazardous properties of chemicals and other hazardous agents. Chemical companies provide such data sheets, and collections of SDS sheets are available from several sources.

02

Material

The materials used are standard requirements by construction code, we assure quality products from our custom fabrication to the brands we use.

03

Experience

Having over 40 years of experience, Plastic works systems offers a wide array of sustainable products. Our longevity has been based on great customer relationship. With experience we recognize what products work best for desired applications.

Our Skills

Fabrication

Our shop has been setup in order to deliver most sought out products. The products we are known for producing are indicated here. Should you have any questions regarding any of these categories please contact us.

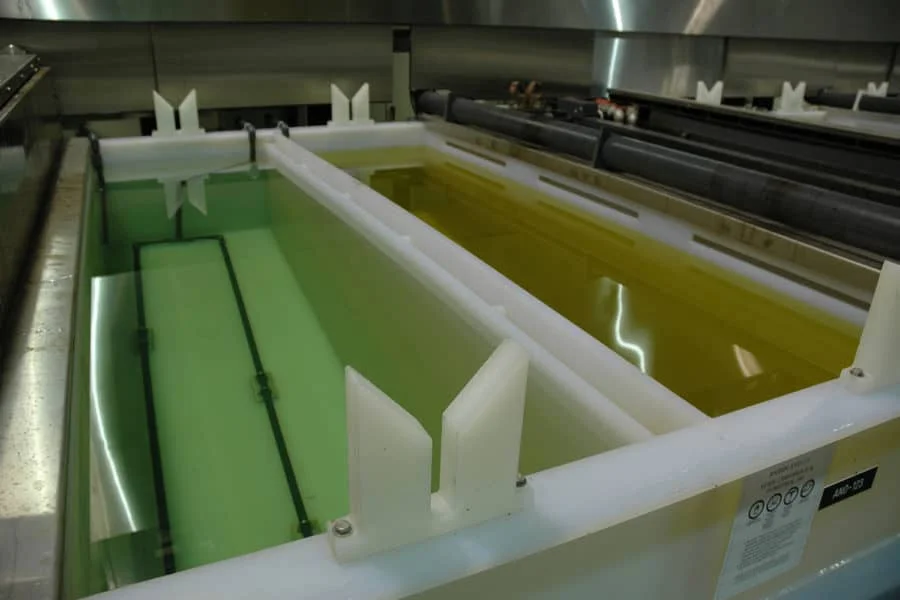

- GREASE TRAPS & OIL SEPARATORS

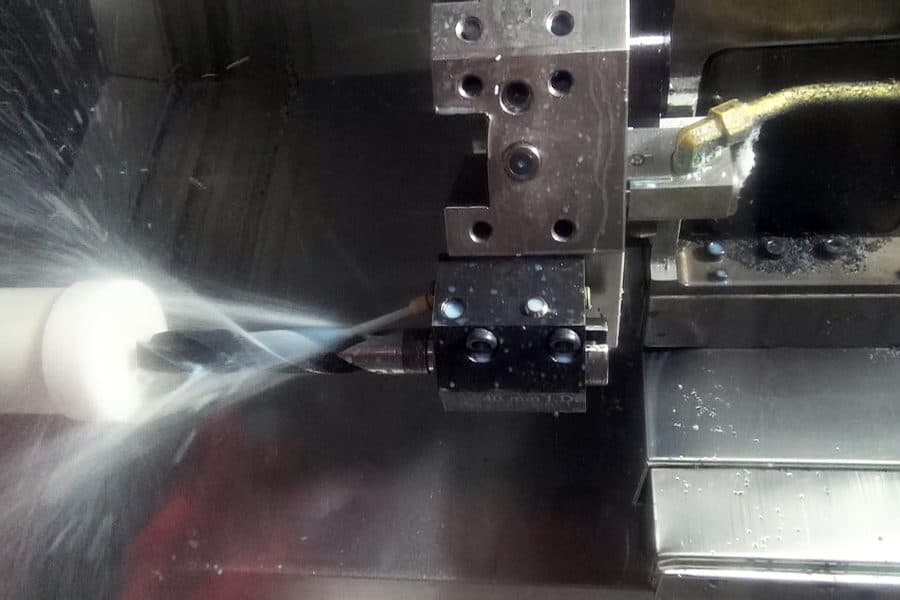

- CNC PRECISION CUTTING

- RETRO FITS

- WATER TREATMENT

- HEATING EQUIPMENT

- CUSTOM FABRICATION

- VENTILATION

- PUMPS

- REPAIR & INSTALLATION

- MACHINING

Thoughts

Our Latest Posts

About Process Technology

Process Technology are passionate about our products. Process Technology loves the products we build and are excited about creating thermal...

Read More

About FloKing

Flo King is the four-in-one, in-tank system that pumps, filters, agitates, and treats electroplating, anodizing, printed circuit, low-sludging iron phosphate, and...

Read MoreGet Social

Follow Us Right Now

Follow us on social media, learn about new processes and products we offer.

Transparency

Great client relations. Keeping the lines of communication open during the build is essential. Making sure all jobs run perfectly this requires a clear understanding of how the desired job should proceed.

Clients & Partners

We Love Our Clients

Thanks Stew!